Bearing Blocks

Bearing Blocks

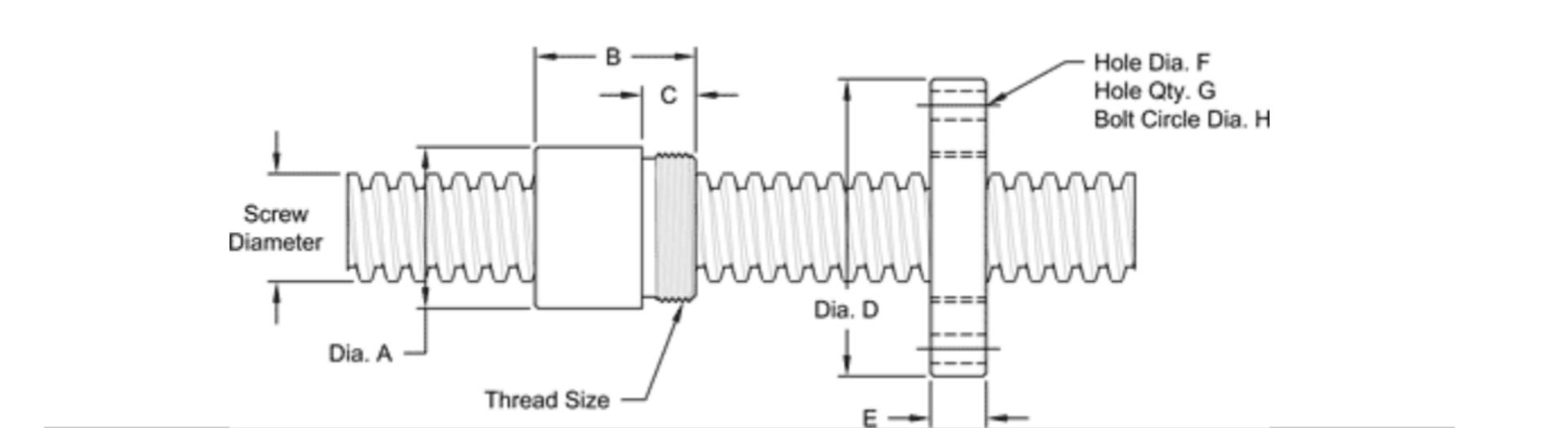

Every screw assembly requires a means of supporting the rotational axis of the screw and absorbing radial and axial force components. Joyce provides a line of bearing block supports for screw and nut assemblies. Standard supports are available for Ball screws, Acme and Stub Acme machine screws, and Metric (trapezoidal) screws. Our bearing mounts are sealed and greased at the factory. They are suited for high duty cycle conditions.

Select the type of screw used in the assembly to view details:

Product Media

A few things to consider when specifying Bearing Blocks.

1. Know Your Load- Bearing blocks used in screw & nut assemblies may not be rated for the same static load as the screws or nuts with which they are used. Understand the loads and types of loads the assembly is likely to encounter and contact Joyce/Dayton to verify that bearing blocks are adequately sized for the required loads.

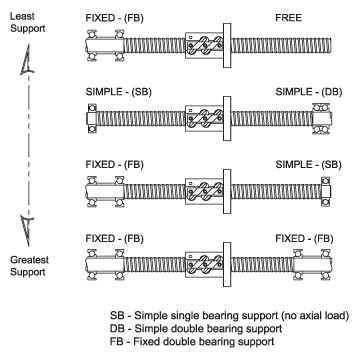

2. Mounting Matters- Choice of mounting type and orientation determine screw and nut selection and allowable screw lengths and operational speeds. An overview is given below.

Simple Single Bearing Supports (SB) - a deep groove radial ball bearing.

- Simple radial supports

- Designed for radial loads only

- Float of bearing in the housing allows for thermal shaft expansion

- Predrilled for face or foot mounting

Simple Double Bearing Supports (DB) - a set of angular contact bearings.

- Simple support

- Designed to support a combination of radial and axial loads

- Predrilled for face or foot mounting

- Industry standard for interchangeability

Fixed Double Bearing Supports (FB) - a set of spaced angular contact bearings.

- Fixed bearing supports increase angular dynamic system stiffness

- Allow greater compressive column strength

- Increase effective length of column and critical speed capability of system

- Designed to support a combination of radial and axial loads

- Predrilled for foot mounting

- Predrilled taper pin reaming to suit final assembly