Protective Bellows and Covers for Machine Components

Joyce/Dayton Corp. is pleased to announce that Protective Bellows and Covers are now available directly from Joyce. Choose from a variety of sizes, shapes, and materials.

Joyce/Dayton Corp. is pleased to announce that Protective Bellows and Covers are now available directly from Joyce. Choose from a variety of sizes, shapes, and materials.

The new Joyce/Dayton Corp. catalog is your go-to-source for all things lifting and positioning and the perfect place to start every project. The catalog provides more than 190 pages of the most up-to-date information you need to ensure that your next system is successful and to precise specifications.

Join Zeewoo Tech Corporation, one of Joyce/Dayton's valued distributors, at the Korea Machinery Fair 2017 (KOMAF) October 24-27 at KINTEX Hall.

Learn about our innovative drive designs and customer-centric approach to business. At Joyce, we adapt our products to meet your needs.

Semigood Design, LLC approached Joyce/Dayton with a concept for a unique conference room table that combined both bold and functional handcrafted elements. Inspired by the customer’s ingenious concept, Joyce engineers offered a creative, mechanically sound solution. The resulting lifting system was a perfect fit in both form and function.

Joyce/Dayton is pleased to announce JAX® Online, a new web-based linear motion design software application. Intuitive and easy to use, JAX Online software is the fastest way to specify the right jacks and components for ideal lifting and linear motion systems. Because it is web-based, users can access the program from any computer with an internet connection and a modern web browser.

An IP rating denotes a product's ability to prevent the ingress of certain fluids or particles that would negatively impact the functionality of its components. When a piece of equipment is likely to encounter high temperature, high pressure wash down situations and needs to be frequently cleaned without incurring damage, using IP69K-rated equipment is an advantageous solution.

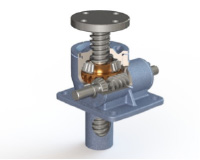

Joyce/Dayton screw jacks and lifting systems offer wide-ranging lifting and positioning solutions for diverse industries. Our robust jacks reliably move and accurately position loads up to 250-tons. Joyce configures jacks with components such as motors, gear reducers, shafting, coupling, and motion control devices to create complete multi-jack systems.

Screw jacks that are properly selected and maintained will reliably lift, position, support or hold industrial loads for years. Incorporating them into mechanized applications is a fairly simple matter once jack designs are understood.

Screw jacks that are properly selected and maintained will reliably lift, position, support or hold industrial loads for years. Incorporating them into mechanized applications is a fairly simple matter once jack designs are understood.

The basic components of machine screw jacks are lifting screw, gear set, and thrust bearing.

Engineers and designers frequently use screw jacks in the design of lifting and positioning equipment. They know that mechanical jacks offer reliable lifting and holding options that can be easily incorporated into their systems.

Screw-driven jacks are the most popular devices used to convert the rotary motion of a motor into linear movement. However, there are two common types of screw-driven systems to choose from: ball screws and lead screws. In this blog, we’ll cover the benefits, drawbacks, and applications of both ball and lead screws to help you determine which option is best for your needs.